Anyang GEMCO Energy Machinery Co., Ltd

Established in 1992, Anyang GEMCO Energy Machinery Co., Ltd (subsidiary of ABC Machinery) deals primarily in manufacturing and exporting of complete briquette machines. Importing and exporting of various mechanical products and engaging in economic and technical cooperation with clients.

Suitable material for briquetting

- Color and black metallic mine powder: Iron scale, iron sludge, Precipitator dust, Iron concentrate, Raw material powder, Manganese ore fines, Silicomanganese alloy. etc..

- Coal: Coal powder, coke powder, slime peat, middle coal,lignite etc.

- Other material:Charcoal powder, fireproof material, Desulfurized gypsum,Dolomite etc

Mine / Coal Briquette |

BBQ Charcoal |

Shisha Charcoal |

Coal Ball |

Metal Briquettes |

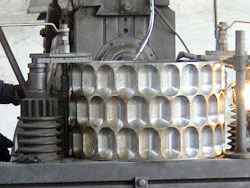

Roller Briquette Press |

BBQ Briquetting Press |

Shisha Charcoal Briquette Machine |

Coal Ball Machine |

Metal Scrap Briquette Machine |

If you raw material is wood, farm waste, etc, you want make biomass briquettes, can click here: www.bestbiomassmachine.com

We design and manufacture 2-30T/H complete briquetting machine, roller briquetting machine, Dry Powder Briquetting Press, screw briquetting machine, Shisha charcoal briquette press, coal ball machine and metal scrap briquette press machine. The finished l briquettes made by our machines are high density, perfectly shaped and have a good appearance.

Briquetting technology

Briquetting is the transformation of a powdery or granular material into a larger more convenient size solid product. This is accomplished by compacting the material with a roller press, sometimes in the presence of a binding material. The briquettes can be produced with high or low pressure and can undergo mechanical or thermal treatment according to the characteristics of the processed material. The binder is used and the desired end product is complete.

Briquetting is the only way to change a powdery material into a briquette which is suitable for transporting and is energy-saving.

Complet Plant of Briquetting Machine

|

|

|

|

|

|

|

|

PDF of Briquetting Press

PDF of Briquetting Press